Dual-Leg Selective Acidizing in Horizontal Carbonate Well

- https://doi.org/10.2118/229918-MS

- Paper Number: SPE-229918-MS

- Paper presented at the ADIPEC, Abu Dhabi, United Arab Emirates, November 2025.

- November 10, 2025

- 2 min read

Successful Design and Execution of Dual Leg Selective and Matrix Acidizing Using Open Hole Inflatable Packer for the First Time in a Horizontal Carbonate Well From one of the Iranian Southwest oil Fields: A Case Study

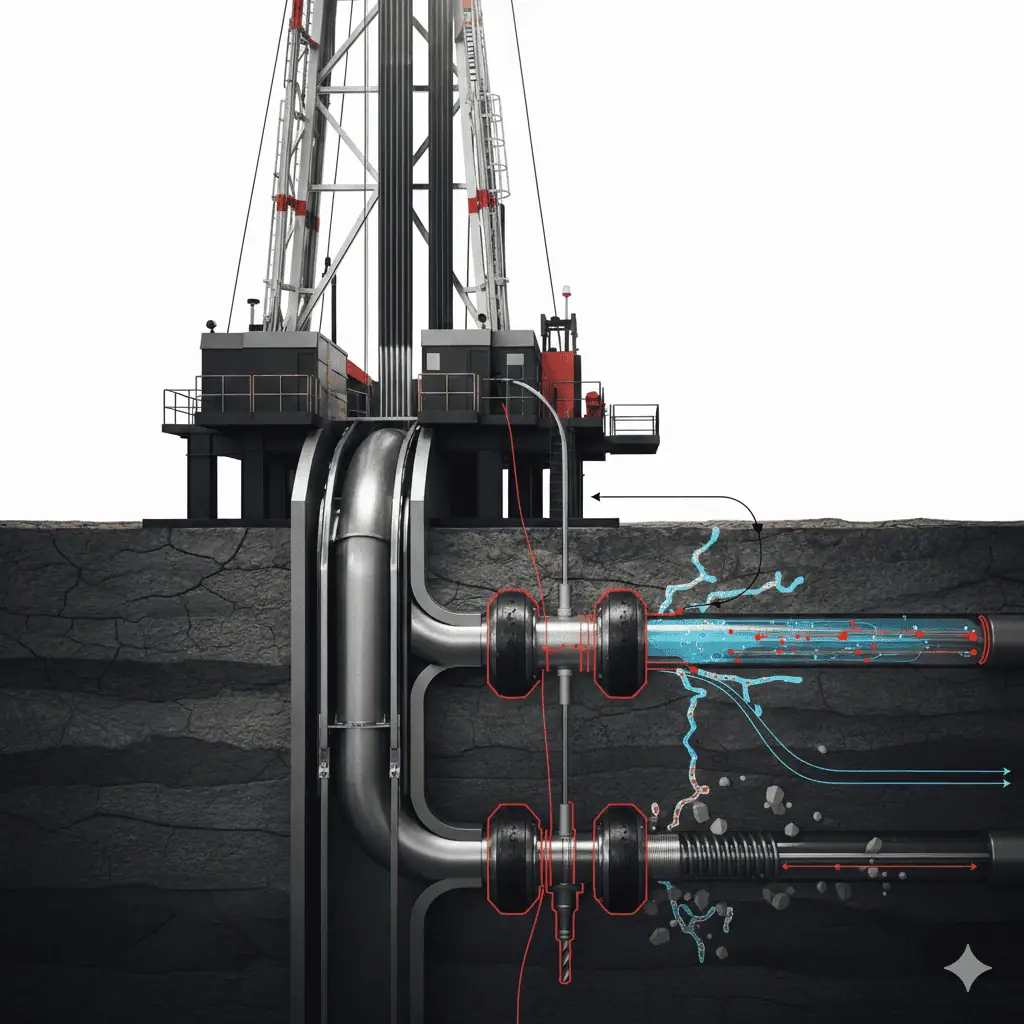

This paper presents a successful stimulation case in a dual-leg horizontal well in the A formation carbonate reservoir, Target field, Iran. The objective is to demonstrate the effectiveness of combining open-hole inflatable packer technology with coiled tubing-conveyed acidizing to selectively stimulate each lateral separately for the first time in Iran. The study evaluates the impact of selective and matrix acidizing on injectivity, productivity, and operational efficiency.

A two steps acid stimulation was executed. In the first step, selective acidizing was performed by isolating each leg using an open-hole inflatable packer deployed on coiled tubing to perform acid wash. In the second step, after post-CT acid wash cleanup, matrix acidizing using plain acid and VDA, enhanced reservoir connectivity through full lateral coverage. Operational steps were supported by integrated simulations using Acid Stimulation Software and Coiled Tubing Hydraulic and Stress Analysis Simulator ensuring accurate fluid placement, retrievable packer setting depths, and pressure-force limits. Post-job well performance was evaluated via injectivity tests and results, multi-choke well testing and production monitoring to assess the effectiveness of the stimulation.

The stimulation delivered significant performance improvements. After selective acidizing, the injectivity index (II) improved from 0.8 to 2.0 STB/(D·psi), and after matrix acidizing, it reached 4.0 STB/(D·psi)—a fivefold overall increase. The surface productivity index (PI) increased from 1.75 to 8.7 STB/(D·psi), while wellhead pressure increased from 170 psi to 870 psi in the same choke size. Oil production improved from 1,800 BOPD to 2,900 BOPD. The use of the inflatable packer enabled precise acid placement in each leg without mechanical failures, packer lock-up, or coiled tubing issues. Diverter efficiency effectively targeting low-permeability sections evaluating by using an advanced analysis methodology. Compared to matrix acidizing alone, the selective approach removed near-wellbore damage more efficiently, while matrix acidizing ensured deeper penetration across the carbonate formation. The integration of both methods resulted in optimal stimulation coverage with improved flow distribution. The operation was successfully executed under a rig-based setup, demonstrating that complex open-hole dual-lateral wells can be effectively stimulated using a combination of mechanical isolation and chemical diversion without compromising operational safety or treatment effectiveness.

This case introduces a novel, dual-lateral stimulation methodology in carbonates, combining mechanical isolation via open-hole inflatable packers deployed through coiled tubing with chemical diversion using VDA pumped through the kick-off string. The workflow, backed by real-time operational simulations and post-job validation, sets a new benchmark for complex horizontal well interventions. The approach enhances stimulation precision, reduces operational risks, and delivers significant cost savings, offering a scalable solution for similar carbonate reservoirs worldwide.

Share this post